Mob # 270 484 6585

Civil Engineering Uses of Diamond Grid

Affordable ground erosion control geogrid & soil stabilization underlayment for permeable infrastructure including road beds, parking lots, driveways, hangars, airstrips, sheds and warehouses. Proven to withstand heavy loads under constant use in mining, agriculture and commercial erosion control construction.

Economical multi-layered drainage system that drains water

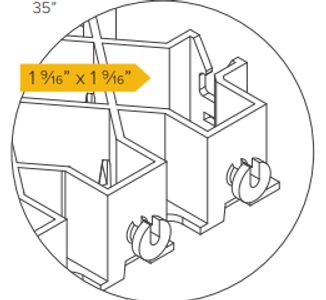

DIAMOND GRID 35″ X 22″ X 1.6″ Our classic grid size is suitable for most rural and domestic applications.

It's unique diamond design allows it to withstand up to 30 TONS/SQ FT when empty and up to 100 TONS/SQ FT when filled.

It's aesthetically pleasing with your choice of fill for numerous possibilities. It is up to 96% permeable making it perfect for heavy rains, flooding areas, and run off. The installation process is fast and DIY friendly. When using concrete as a fill, Diamond Grid reduces concrete by 2 in, completely eliminates rebar, and the need for a pump truck.

Drains water from the surface, reducing erosion and eliminating compaction.

THE DIAMOND GRID INTERLOCKING SYSTEM IS ROBUST AND EASY TO INSTALL.

UV stabilized | Relocatable | Do-It-Yourself | Interlocking system

Crush resistance (filled with gravel/ road base) 100+ tons/sq ft filled* Crush resistance (empty grid) 30 tons/sq ft empty*

Weight per grid 7.05 lbs

Fill ratio per grid 1 cubic yard of fill per 207.9 square ft

Permeability Up to 96%

This honeycomb grid geotextile is a 3-D system for soil stabilization. Simply fill the grid with road base, gravel, pebbles, grass, soil, concrete, asphalt

Tell us about your project

Specifications

CIVIL & MINING APPLICATIONS (pdf)

DownloadCIVIL & MINING INFO & INSTALLATION GUIDE (pdf)

DownloadINSTALL & SPEC OT (pdf)

DownloadCONCRETE REINFORCEMENT (pdf)

DownloadRURAL INFO & INSTALLATION GUIDE (pdf)

DownloadRURAL APPLICATIONS (pdf)

DownloadLANDSCAPE INFO & INSTALL GUIDES (pdf)

DownloadLANDSCAPING APPLICATIONS (pdf)

DownloadSALES SHEET (pdf)

DownloadMinimum Order size

5760 Sq Ft = 20 pallets

54 Grids = 1 pallet = 288 Sq Ft.

DIAMOND GRID VS COMPARABLE SURFACE SOLUTIONS

30 YEAR COST COMPARISON

Installation & Application Videos

US National Guard Testing Of Diamond Grid With their Extreme Heavy Duty Recovery Transporter vehicles

Concrete Installation Process.

Diamond Grid - Mining Applications as a gravel grid using crushed gravel.

Functions of Diamond Grid in Civil Engineering projects

Functions of Diamond Grids

Improves sub grade/road base performance

Structural Benefits of Diamond Grids

Soil Stabilization: When base material is compacted within geogrids the base material is “seated” locking the aggregate in fixed position.

Base Reinforcement & Confinement: Geogrids keep fill material in place and aids interlocking granular base.

Stress Transfer: Achieved by distributing applied loads over a greater area and thus reducing vertical pressure on the sub-grade.

Structural Benefits of Diamond Grids

Improves sub grade/road base performance

Structural Benefits of Diamond Grids

- High Junction Strength

- High Mechanical Interlock

- High Resistance

- High Tensile Modulus

- High Tensile Strength

Improves sub grade/road base performance

Improves sub grade/road base performance

Improves sub grade/road base performance

They have been found to:

- Aid in erosion and sediment control

- Enhance containment projects

- Improve subsurface drainage & filtration

- Stabilize roadways & railroads

- Maintain structural base

- Reinforce soils

- Stabilize roadways & railroads

Benefits of Economical Diamond Grid Erosion Control

Reduce subgrade thickness

Increase road load bearing capacity

Works as a bridging layer to spread load across the ground

Cut maintenance frequency up to 70%

Cut maintenance costs up to 70%

Holds the road together for longer periods

Increase traffic load without increasing pavement thickness

Minimizes pavement failure due to semi-rigid load bearing capacity

Act as a bridging layer for differential settlement

Less vehicles and staff will be required as vehicles will be able to get from point to point in half the time

Increases the fuel economy of the vehicle as they can travel up to 50-75% faster on safe, level and solid roads

Reduces vehicle accidents as with Diamond Grid the roads are free of potholes, corrugation

Contact Us

Hours

Today | Closed |